5 Reasons your Process Could Benefit from Glass-Lined Steel Equipment

Glass-lined steel process equipment is used in virtually all of the world’s pharmaceutical manufacturing facilities and is also widely employed by the chemical, petrochemical, pesticide, metallurgical and food industries. There are several advantages in the unique characteristics of glass lining that make this material of construction a top selection of design engineers. Here are 5 key reasons why glass-lined steel can benefit your process:

Glass-lined steel process equipment is used in virtually all of the world’s pharmaceutical manufacturing facilities and is also widely employed by the chemical, petrochemical, pesticide, metallurgical and food industries. There are several advantages in the unique characteristics of glass lining that make this material of construction a top selection of design engineers. Here are 5 key reasons why glass-lined steel can benefit your process:

-

Corrosion Resistance

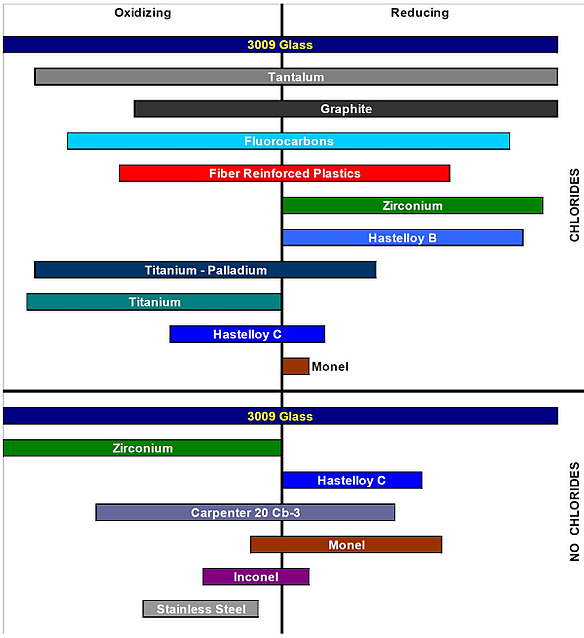

Glass-lined steel provides superior corrosion resistance to acids, alkalis, water and other chemical solutions (with the exception for hydrofluoric acid and hot concentrated phosphoric acid). As a result of this chemical resistance, glass lining can serve for many years in environments that would quickly render most metal vessels unserviceable. The chart shown below illustrates how glass lining has the widest range of corrosion resistance of any material used for equipment. This makes the use of glass lining mandatory in some processes.

-

Flexibility

The chemical, mechanical, and thermal properties of glass are proof that this material can handle a diverse range of operating conditions. Users of glass-lined equipment are therefore able to make drastic changes to their process with no added investment for new equipment needed. This versatility makes glass-lined steel the equipment of choice for research and development projects, batches that require frequent change out, and other multifaceted applications.

-

Purity

Aggressive reaction environments tend to dissolve metals from unlined mild steel or alloy reactors. Extractable metals, such as chromium, nickel, molybdenum, and copper, can leach into and contaminate your product, producing undesired catalytic effects that can cause harmful fluctuations in the process reactions. These metals can compromise product quality, negatively affect product yield, and in some cases even cause runaway reactions. Glass-lined steel is inert so it is impervious to contamination. Additionally, it does not adversely affect flavor or color, which is of extreme importance to food and drug applications where purity is essential.

-

Ease of Cleaning

Especially in the case of pharmaceutical processes, cleanability is critical. Between batches, each reactor and its associated process equipment must be thoroughly cleaned in order to assure product quality and minimize heat transfer resistance caused by product buildup. Glass-lined steel has been adapted to cGMP requirements for cleaning, cleanliness, and sterilization. Its high degree of surface smoothness makes it easy to clean using non-corrosive, low pressure cleaning systems. The smooth surface of glass-lined steel also resists the buildup of viscous or sticky products, which means less frequent cleaning.

-

Economy

When properly handled and maintained, glass-lined steel reactors can be a cost-efficient solution compared to steel and alloy vessels, whose service life can be drastically shortened due to their inability to resist corrosion the way glass lining can. The combination of glass and steel provides you with the best of both materials of construction; fusing glass to steel produces a composite material with an inside that offers product protection and an outside that provides structural strength and durability.

If you think glass-lined steel is a right fit for your process, we suggest reading our “Introductory Guide to Glass-Lined Steel Equipment.” This complimentary eGuide provides a more in-depth look at glass lining technology with insight on its history, fabrication, and chemical, mechanical and thermal properties.