5 Tips for Handling Compressed Air

Compressed air is used in all industries in a variety of different ways. Depending on how or where you are using it, the design of your compressed air lines can be a key factor to optimizing its functionality. At De Dietrich Process Systems, we have utilized air in a variety of ways. Some examples include:

Compressed air is used in all industries in a variety of different ways. Depending on how or where you are using it, the design of your compressed air lines can be a key factor to optimizing its functionality. At De Dietrich Process Systems, we have utilized air in a variety of ways. Some examples include:

- Using linear actuators to move objects

- Opening and closing process valves

- Powering air-driven motors to raise/lower drive assemblies

- Fluidizing gas to aid in the flow of solids out of hoppers or in transfer lines

While we may not design compressed air lines, we’ve learned a lot from our experience integrating them with our equipment and have picked up a few tips that can make your job easier.

Note: This blog is intended as a high-level overview to show some common practices when handling compressed air. Any of the tips listed below should be reviewed by trained personnel to determine best ways to implement if needed or desired.

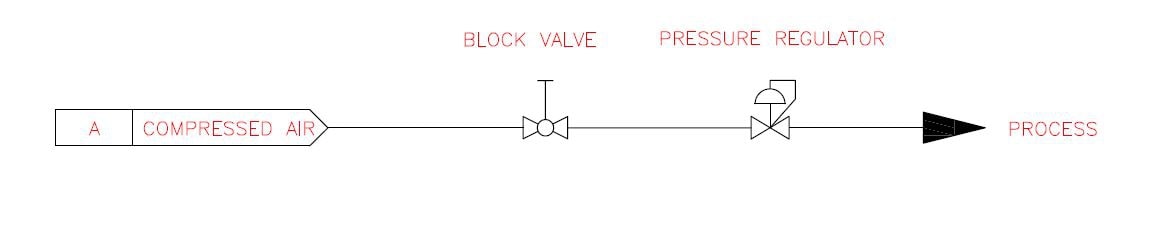

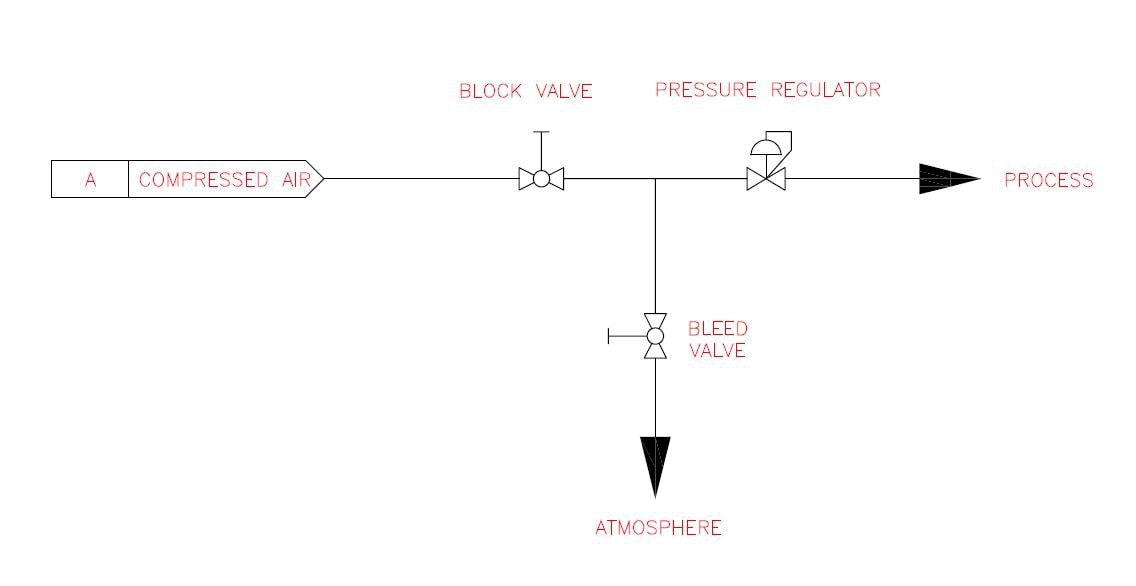

Tip #1: Install a Block Valve

A block valve, also known as a shut-off valve, is used to stop the flow of gas to a piece of equipment or process. Installing one at or near the point-of-use makes it easier for trained personnel to shut off the air supply without turning off the compressor. This is essential to maintaining uptime and being able to safely troubleshoot or maintain a piece of equipment.

Tip #2: Install a Bleed Valve

While a block valve may isolate a piece of equipment, it does not provide a means to relieve the pressure downstream of the valve. That’s where a bleed valve comes in. Once the block valve is closed, the bleed valve can be used by trained personnel to safely de-pressurize the line, making it safe to work on the downstream equipment or process. While there are some instances where a bleed valve is not necessary, for safety reasons, the majority of systems that have a block valve installed should also have a bleed valve in place.

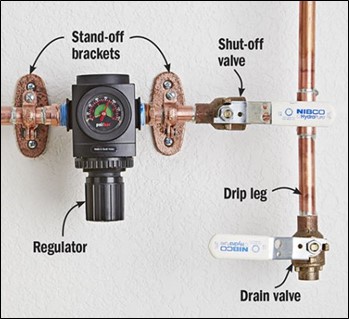

Tip #3: Add a Drip Leg to Remove Moisture

A “drip leg” is a simple and inexpensive concept. When dealing with air lines that might have high moisture content or experience temperature changes that result in condensation, it’s important to be able to remove this moisture from the line. While there are specific devices to deal with moisture, one viable option is the drip leg. It is comprised of a piece of the pipeline that extends vertically downward, providing a means to capture water droplets in the airline and prevent or reduce them from flowing through other devices or into a process. Drip legs can often be combined with bleed or drain valves or other types of valves that allow accumulated moisture to be drained from the line. While this doesn’t guarantee the moisture will not travel farther down the line, it is a great first line of defense to prevent it from doing so.

Tip #4: Make Sure Your Air is Dry

There are several ways to go about drying air. Before determining how to dry your air, it’s very important to know how dry it needs to be. See the table below for different ISO classifications:

| ISO 8573-1:2001 CLASS | Water | |

| Dewpoint | Liquid g/m3 | |

| 0 | As specified by the equipment user or supplier | |

| 1 | -70°C | |

| 2 | -40°C | |

| 3 | -20°C | |

| 4 | +3°C | |

| 5 | +7°C | |

| 6 | +10°C | |

| 7 | 0.5 | |

| 8 | 5 | |

| 9 | 10 | |

The classification of air required should be available from an equipment manufacturer. Some pieces of equipment may be designed for harsh environments and the quality of air may not be as critical. Regardless, it is something to always keep in mind. Most of the time, equipment will perform better and last longer with drier air.

The drying equipment you need will depend on which Class of air you require. Bear in mind that the lower the classification number (i.e. the more stringent the classification), the more expensive it will be. Below is a list of some different items to consider that can help you reach your specific classification requirement.

- Drip Leg (mentioned above).

- Filter Regulator with Water Trap – Uses cyclonic effect to capture water from air stream and deposits in bowl for draining. Low cost and recommended at point-of-use.

- Aftercooler on compressor – Can remove up to 70% of moisture.

- Refrigerant Dryer – 2°C to 10°C dewpoint. Lower upfront costs. Higher operating costs.

- Regenerative Desiccant Dryer – Can easily deliver -40°F (-40°C) dewpoint. Higher upfront costs. Lower operating costs.

For any specific questions about drying your air, we recommend consulting a compressor manufacturer.

Tip #5: Separate Process Air from Instrument Air

First, let’s define process air and instrument air. Process Air is used inside the process. For example, with pneumatic conveying, air is often injected into the conveying lines to help move material. Because this air interacts with the product, it would be considered inside the process. On the other hand, instrument air is often higher pressure air used to operate things like actuators or air motors. This type of air does not go into the process.

Because these types of air have two different purposes, it’s important they remain separated as much as possible. As such, you will likely need to condition these air supplies differently to remove moisture and particulates and regulate pressure and flow. Once the requirements for the air inside and outside the process are determined, the proper steps can be taken to condition and manage the air to help ensure the process and equipment are receiving the quality of air needed.

Air compressors can be an integral part of a pneumatic conveying solution. Following these tips will help you to optimize your system so it operates safer and more efficiently. At De Dietrich Process Systems we specialize in dense phase transfer, making it possible for our customers to convey material in a safe and contained manner. If safety is important to you (as it should be for any process that involves operators and machinery working together) and you'd like to discuss your solids handling needs in more detail contact us. Or, if you are interested in other safety-themed content, download our whitepaper on Safely Charging Solids into Process Reactors.