Eight Advantages of Vacuum Conveying: A Breath of Fresh Air

In the vast realm of material handling, vacuum conveying is amongst the top options available. While pneumatic conveying as a whole is widely appreciated, the vacuum variation of it offers specific benefits that can be particularly appealing to certain industries and applications. In this blog post, we’ll explore the myriad of advantages for vacuum conveying and why it might just be the solution you're looking for.

Advantage #1: Enhanced Safety and Hygiene

- Containment: Vacuum systems are enclosed, reducing the risk of material leakage or spillage. This containment is especially crucial for industries handling toxic, volatile, or sensitive materials.

- Dust Control: Vacuum systems inherently reduce the suspension of dust, resulting in a cleaner and safer working environment, which is particularly important for sectors like pharmaceuticals and chemicals.

Advantage #2: Versatility in Material Handling

- Diverse Materials: From fine powders to granules, vacuum conveying can handle a variety of materials without issue.

- Multiple Pick-up Points: Unlike pressure systems, vacuum systems can efficiently manage multiple pick-up points, which can be beneficial in batch processing or when materials are sourced from different locations.

Advantage #3: Space Efficiency

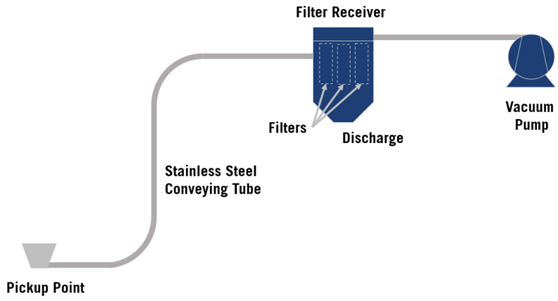

- Compact Design: Vacuum conveyors generally have a more compact design, specifically the filter receiver, than their pressure counterparts, allowing for easier integration into facilities with space constraints.

- Flexible Routing: The system can navigate around obstacles, manage vertical lifts, and even handle intricate plant layouts, providing considerable flexibility in installation.

Advantage #4: Lower Maintenance Needs

- Less Wear and Tear: Given that materials in vacuum systems often move at a lower velocity compared to dilute phase positive pressure systems, there's typically less deterioration of the equipment.

- Easier Clean-up: In the event of a material change or system cleaning, vacuum systems are generally easier to clean due to their design and the nature of their operation.

Advantage #5: Energy Efficiency

- Optimized Air Volume: Vacuum systems use only the air volume necessary for conveying, potentially resulting in some energy savings over time.

- Adaptability: The ability to adjust the system's operation based on material volume and type can lead to further energy optimizations.

Advantage #6: Ease of Installation and Expansion

- Modular Design: Many vacuum conveyors come in a modular design, simplifying both the initial installation and future expansions or modifications.

- Less Piping: Typically, vacuum systems require less piping than pressure systems, making installation quicker and less intrusive.

Advantage #7: Gentle Material Handling

For fragile or easily degradable materials, vacuum conveying can offer a gentler transport method, ensuring that the material's integrity is maintained throughout the process.

Advantage #8: Simplified Discharge

Vacuum systems can more easily discharge materials into containers under atmospheric pressure or even into systems under positive pressure, offering flexibility at the receiving end.

Vacuum conveying, with its unique set of advantages, stands as an attractive option for industries looking to efficiently and safely transport bulk solids. Whether you prioritize hygiene, space efficiency, or gentle handling, vacuum conveying, like the Powder Pump solution offered by De Dietrich, offers a tailored solution that can fit seamlessly into your operations. As always, consult with a conveying specialist like De Dietrich to determine the best system for your specific needs and challenges.