Material of Construction Options for Chemical Process Plants

When it comes to building a process plant, there are many material of construction options for you to consider. For some plants, the application itself can dictate what MOCs are needed. Previous experience, continuity and plant standards can also play a crucial role in this decision.

When it comes to building a process plant, there are many material of construction options for you to consider. For some plants, the application itself can dictate what MOCs are needed. Previous experience, continuity and plant standards can also play a crucial role in this decision.

Common building materials used for process plants include carbon steel, stainless steel, steel alloys, graphite, glass, titanium, plastic, Monel, and many more. For this discussion let’s focus on materials of construction that are used for highly corrosive and abrasive media.

Selection Variables

There are several variables that should influence your decision when selecting the best material of construction for your plant. The three major ones are:

- Corrosion resistance – What chemicals are you processing? You’ll need to be conscious of selecting materials that comply with the chemical composition of your process to ensure it will perform to your expectations.

- Cost – What is your budget? Capital expenditures need to be taken into consideration to ensure you don’t exceed the financial limits for the project.

- Expected operating life – How long do you plan to keep your system in operation? Whether it’s a continuous or batch process, how frequently it is run, and how many years of service you hope to get out of it are all questions that need to be accounted for when you are determining what type of system components to employ.

There are other minor variables such as compatibility of material of construction with existing plant installations, plant operating conditions, ease of maintenance, and cleaning requirements to name a few. While these are less critical, they are still important to keep in mind as you establish the criteria for your plant.

Corrosion Resistant MOC Options

When looking at materials of construction for highly corrosive media your options are more limited. Depending on your operating conditions and the actual media being processed in your plant you will most probably end up with a combination of materials, including:

- Hastelloy C-276 –A nickel-molybdenum-chromium superalloy that contains tungsten to give it excellent corrosion resistance in a wide range of severe environments.

- Inconel 600 - Typically used in high temperature applications, this material forms a thick oxide layer when heated to protect the surface from chemical attack.

- Titanium – This alloy combines high strength with low density to provide good corrosion resistance across a range of temperatures and is advantageous in applications that benefit from weight savings (e.g. aerospace structures)

- Tantalum – Offers outstanding resistance to aqueous solutions and metal melts with a high melting point, superconductivity, and biocompatibility.

- Monel 400 – A nickel-copper alloy that is resistant to sea water/salt solutions and steam at high temperatures as well as caustic solutions.

- Plastics (PFA, PP, FRP, TEFZEL) – A variety of plastic polymers can be used to provide extended service in hostile environments, offering excellent mechanical stress resistance as well as stability at a wide range of temperatures.

- Glass – Available as Borosilicate 3.3 glass (i.e. QVF SUPRA-Line) and glass-lined steel. We’ll dive into this more in the next sections.

Glass Benefits and Limitations

Because of the traditional “look and feel” of a process plant, glass might not be a first choice that will come to mind, but for many applications glass could be your most economical and optimum solution. Here, we’ve noted the top benefits of using glass components:

Excellent Corrosion and Chemical Resistance

Glass equipment provides unsurpassed corrosion resistance to saline solutions, organic substances, halogens such as chlorine and bromine, alkaline mixtures, and many acids (nitric acid, sulfuric acid, hydrochloric acid). Its resistance to chemical attack is superior to that of most metals and other materials, even during prolonged periods of exposure and at temperatures above 100 °C. The corrosion resistance glass offers also applies to the exterior, making glass a good choice for corrosive plant environments. And if you have concerns about corrosion rates, there are simple methods to measure the wall thickness of your equipment to keep track of how its holding up to your process.

Ideal Surface Properties

Some materials of construction can pose housekeeping issues when it comes to ease of cleaning. Not glass! With an anti-adhesive and nonporous surface that resists the buildup of viscous or sticky products, borosilicate glass is a popular choice for processes where ease of cleaning is critical. And its transparency allows you to see when equipment needs to be cleaned without the need for interrupting the process and performing an internal inspection. More on that subject ahead…

Unmatched Visibility

Unlike most plastic and metal materials, glass equipment provides transparency to give you an unobstructed view of what is going on inside your system, enhancing the observation of your process. For photosensitive substances, brown coated glass is also available to offer extra protection. And if you have concern over potential mechanical stresses inflicted on the glass, Sectrans coating is available; this optional covering is applied to the glass surface to add protection against scratches, blows and splintering.

Chemical Inertness

Aggressive reaction environments tend to dissolve metals from unlined mild steel or alloy reactors. Extractable metals, such as chromium, nickel, molybdenum, and copper, can leach into and contaminate your product, producing undesired catalytic effects that can cause harmful fluctuations in the process reactions. These metals can compromise product quality, negatively affect product yield, and in some cases even cause runaway reactions. Because there is no interaction or ion exchange between the process media and glass, there is no catalytic effect and no contamination. The inertness of borosilicate glass also means it is nonflammable and therefore approved for installation in explosive atmospheres.

As with any option, there are a few limitations of glass that we need to address:

Incompatible Solutions

There are only a few chemicals which can cause noticeable corrosion of the glass - hydrofluoric acid, concentrated phosphoric acid and strong caustic solutions at elevated temperatures. However, at ambient temperatures caustic solutions up to 30% concentration can be handled by borosilicate glass without difficulty.

Size Range

While some may consider the compact design of glass to be a benefit in many plants where space is at minimum, there are certain instances where the available size range of glass can be restrictive for systems that need to process larger volumes. Vessels, columns and heat exchangers have a limiting diameter of 1000 mm (39.4 inches) when built out of Borosilicate glass. If the size limitation is a problem for your plant, a combination of glass-lined products and glass components can be your solution.

Operating Precautions

Additionally, there are some limitations related to mechanical and thermal shocks that aren’t applicable to other materials of construction. While some extra precautions do need to be taken, the material does have a wide operating range and can operate reliably and efficiently if the proper guidelines are followed. We’ve included some technical information for the QVF SUPRA-Line that provides more in-depth data regarding some basic operating guidelines as it relates to the thermal and mechanical properties of glass.

Thermal Properties

|

Operating temperature |

TS = 200 °C |

|

Temperature differences between inside and outside |

ΔΘ ≤ 180 K |

|

Individual film heat transfer coefficient inside |

αi = 1200 W/m2·K |

|

Individual film heat transfer coefficient outside |

αa = 1200 W/m2·K |

Permissible Operating Pressures

|

Cylindrical Glass Items |

|||||||||||||

|

DN |

15 |

25 |

40 |

50 |

80 |

100 |

150 |

200 |

300 |

450 |

600 |

800 |

1000 |

|

PS (bar g) |

4 |

4 |

4 |

4 |

3 |

2 |

2 |

1 |

1 |

1 |

1 |

1 |

1 |

|

Spherical Vessels |

|||||||

|

V(I) / D(mm) |

5/223 |

10/280 |

20/350 |

50/490 |

100/610 |

200/750 |

500/1005 |

|

PS (bar g) |

1 |

1 |

1 |

1 |

0.8 |

0.6 |

0.3 |

Mechanical Properties

|

Tensile and bending strength |

K/S = 7 N/mm2 |

|

Compressive strength |

K/S = 100 N/mm2 |

|

Modulus of elasticity |

E = 64 kN/mm2 |

|

Poisson’s ratio (transverse contraction figure) |

v = 0.2 |

Glass-Lined Steel Benefits and Limitations

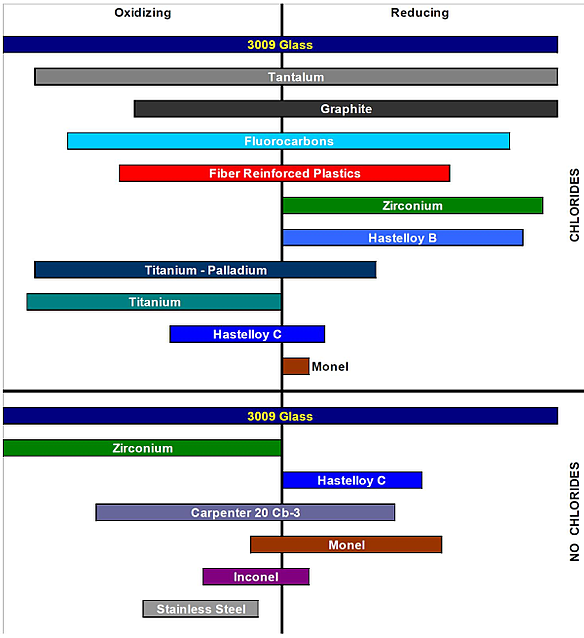

So how does glass-lined equipment compare to glass components? When would you want to use glass-lined equipment in your process plant over glass? When it comes to the benefits of glass-lined components, the list of advantages is almost identical to that of glass (except for visibility, of course) because glass lining is similar in composition to borosilicate glass. Glass-lined steel provides you with the best of both materials of construction; the external steel construction provides structural strength and durability while the internal glass lining gives nearly universal corrosion protection and a smooth, non-contaminating surface. The result of this is corrosion resistance to both acids and bases and equipment that is suitable for high pressure and full vacuum at elevated temperatures. The chart shown below illustrates how glass lining has the widest range of corrosion resistance compared to alternative materials of construction. This makes the use of glass lining mandatory in some processes.

As we touched upon earlier, glass-lined components are a good solution if you need larger sizes that glass can’t accommodate. Glass-lined vessels are available in sizes up to 25,000 gallons and glass-lined columns can range from 6” to 84” diameters. Conversely, glass-lined equipment has a lower resistance to corrosive plant environments than glass components and determining wall thickness for corrosion testing purposes is more complicated than with glass. Glass-lined equipment has some additional limitations regarding temperature and pressure ratings, but if you follow the guidelines of your equipment and take some common-sense cautions, you can minimize or eliminate any risks of thermal or mechanical stresses or shock.

Don’t be Afraid

Although glass may not be your first “go-to” material of construction for your new plant, with the wide range of benefits demonstrated here, glass could be your best solution. Don’t be afraid of working with glass! The resistance and versatility of the material, especially when applied to highly corrosive and abrasive operations, can increase the operating life and capabilities of your system.

If you would like more information about our complete plant solutions and working with glass for your next plant upgrade or new process, contact us and one of our highly qualified personnel will gladly help you.

Click on this link for more information about our borosilicate glass components and to view the catalog: