Understanding the Differences: Glass-Lined Reactors vs. Stainless Steel Reactors

In the world of chemical processes and manufacturing, the choice of the right reactor is crucial for efficient and safe operations. Among the myriad of options available, glass-lined reactors and stainless steel reactors are two of the most popular. Let's delve into the advantages and disadvantages of each to help you make an informed decision for your specific processing needs.

In the world of chemical processes and manufacturing, the choice of the right reactor is crucial for efficient and safe operations. Among the myriad of options available, glass-lined reactors and stainless steel reactors are two of the most popular. Let's delve into the advantages and disadvantages of each to help you make an informed decision for your specific processing needs.

Glass-Lined Reactors

Glass-lined vessels are not a new technology. The first glass-lined reactor was manufactured over 150 years ago. Their ability to resist corrosion and provide a chemically inert processing environment have maintained their status as an optimal technical solution for chemical and pharmaceutical processing applications.

Glass-lined reactors are built using glass enamel that is thermally fused onto the surface of carbon steel at a high temperature, in multiple phases, until an optimal glass thickness is achieved. (For the full story, read our post on How Glass-Lined Vessels are Made).

Here’s a rundown of what makes them so great, and also some limitations that come along with this unique material of construction.

Glass-Lined Steel Pros

- Corrosion Resistance: Glass lining offers exceptional resistance to a wide range of chemicals including acids, alkalis, water, and other chemical solutions, making these reactors ideal for harsh chemical environments. In fact, many severe service applications utilize glass-lined steel because it is the only viable option for their process.

- Clean Operation: The non-stick nature of glass prevents materials from adhering to the reactor walls. This ensures purity in products and simplifies cleaning.

- Thermal Shock Resistance: Glass-lined reactors can withstand sudden temperature changes, which is vital in processes that involve heating and cooling cycles.

- Imperviousness: Aggressive reaction environments tend to dissolve metals from unlined mild steel reactors. Extractable metals, such as chromium, nickel, molybdenum, and copper, can leach into the process and contaminate the product, compromising its quality, negatively affecting product yield, and in some cases even cause runaway reactions. Glass-lined steel is inert, so it is impervious to contamination. Additionally, it does not adversely affect flavor or color, which is critical to applications where purity is essential.

Glass-Lined Steel Cons

- Fragility: Glass is more susceptible to damage from mechanical impacts and thermal stress, leading to potential cracks and chips.

- Limited Operating Conditions: Glass-lined reactors may not be suitable for very high temperature and pressure conditions.

- Higher Cost: The manufacturing process of glass lining is complex and costly, which is reflected in the price of these reactors.

Glass-Lined Steel Restoration Options

When glass-lined vessels are in need of repair or refurbishment, reglassing is the optimal solution. This involves sending your old or damaged vessel to a glass-lined equipment manufacturer where they will ensure the steel substrate is a candidate for reglass, remove the existing glass lining and reapply the glass enamel, essentially creating a “like new” vessel. For more information, read our post dedicated to the reglass process.

There are many benefits to reglassing a vessel over purchasing a new piece of equipment, namely:

- Delivery – The turnaround time to reglass is within weeks versus months to fabricate a new vessel.

- Cost savings - Typically costs a fraction of the price of a new vessel.

- Cash flow - Many companies find reglassing, which is a maintenance budget expenditure, preferable to a new capital expenditure.

- Warranty - All vessels reglassed by De Dietrich come with the same warranty as new vessels. (De Dietrich also offers reglassing on competitors' equipment!)

- Upgrades – Want to add OptiMix wall-mounted baffles to your vessel? Could your process benefit from having additional nozzles on the top head? These refurbishments and more can be made during reglassing.

Stainless Steel Reactors

Invented in 1912 in the UK, stainless steel is an inorganic chemical combination of iron, chromium and nickel. Since its discovery, it has been widely adopted in the chemical processing industry due to its resistance to corrosion, stains, and heat as well as its durability.

Stainless steel also has many use cases that prove these reactors to be a popular choice in certain processing environments. It also has its share of advantages and disadvantages, outlined below.

Stainless Steel Pros

- Durability: Stainless steel is known for its strength and resistance to wear and tear, making these reactors long-lasting and resilient to physical impacts.

- Versatility: These reactors can handle a wider range of temperatures and pressures, making them suitable for a variety of chemical processes.

- Ease of Fabrication: Stainless steel reactors can be manufactured in various shapes and sizes, offering flexibility in design and capacity.

Stainless Steel Cons

- Corrosion Concerns: While stainless steel is generally resistant to corrosion, certain chemicals can cause pitting and corrosion over time, which can contaminate and compromise the quality of the products being processed in the equipment. This is especially of concern for fine chemical and pharmaceutical applications, where the product is typically of very high value. In some applications, the material does not have adequate properties to handle chemical attack or the corrosive attack of biofilm components. Over time, as the ingredients are lost, the chance of iron oxidation increases and therefore, corrosion will occur. Despite being corrosion resistant, it can and will rust in certain conditions – although not as quickly or significantly as plain steels.

- Cost of Material: High-quality stainless steel can be expensive, especially alloys that offer higher corrosion resistance.

- Temperature Sensitivity: Under extreme temperatures, stainless steel can deform or lose its strength, limiting its use in very high-temperature processes.

Stainless Steel Restoration Options

Stainless steel does have some options available to improve and prevent the impacts of corrosion, but keep in mind these treatment methods can be costly, time-consuming, and are only temporary fixes.

Passivation is a chemical treatment process that uses nitric or citric acid to remove free iron from the equipment’s stainless steel surface. It also promotes the formation of a passive chromium/nickel oxide layer that acts as a barrier to further corrosion.

Electropolishing is a procedure used to remove surface defects from stainless steel. It is performed by soaking the material in an acidic bath to remove contaminants and defects from the surface, leaving a shiny and smooth finish.

Both glass-lined and stainless steel reactors have their unique advantages and limitations. The choice between them should be based on the specific chemical processes they will be used for, the operating conditions they need to withstand, and budget considerations. By understanding the pros and cons of each, you can select the reactor that best meets the needs of your chemical processing and manufacturing operations.

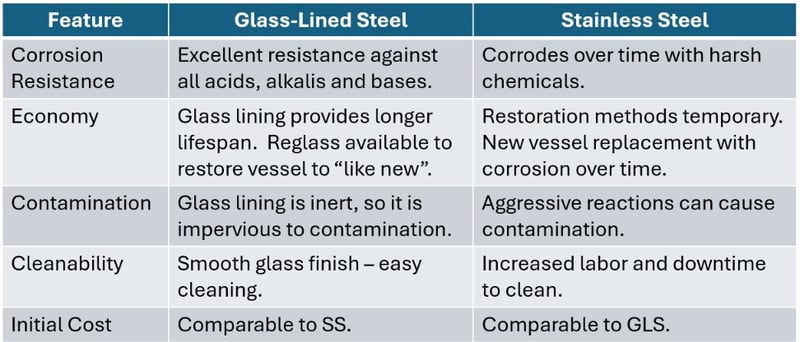

Here's a recap:

Steel Stainless Steel

With glass-lined steel, the result is an affordable, superior solution ideal for chemical and pharmaceutical processes, which offers increased equipment durability, hardness and chemical resistance compared to other materials.

De Dietrich specializes in glass-lined reactors and equipment for chemical and pharmaceutical processes. Our vessels range in size and design to accommodate a wide range of process needs. Contact us for more information, or download our Introduction to Glass-Lined Equipment White Paper.