As mentioned in the overview, De Dietrich Process Systems was tasked with conveying Zinc Oxide powder from FIBCs into an agitated reactor. Zinc Oxide, along with various other metal oxides, is well known for its cohesive nature and when these types of powders are handled in hoppers, flow problems such as bridging and ratholing can occur.

When bridging, also referred to as arching, occurs in a hopper, it is an indication the hopper’s outlet opening is too narrow, and the cohesive strength of the powder is great enough to support a stable arch across the opening.

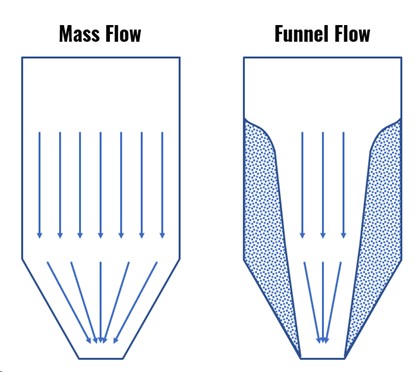

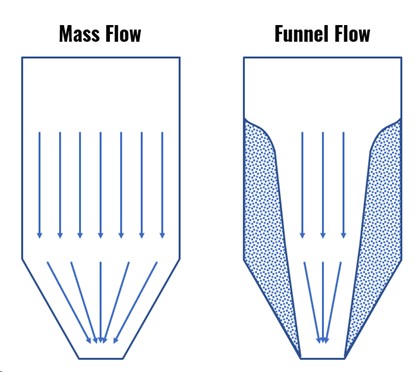

When ratholing occurs in a hopper, it is an indication the outlet is incorrectly sized, and the hopper’s walls are not steep enough to establish mass flow. Funnel flow within hoppers can be employed if the outlet diameter exceeds the critical rathole diameter which can be determined by measuring the internal cohesive strength of the powder and the friction level between the solids and the hopper’s wall.

Image: Mass Flow Profile (left) exhibits uniform flow throughout the cross-section of a hopper. Funnel Flow Profile (right) exhibits preferential flow through the center. Funnel flow can sometimes lead to product separation or ratholing but can also allow smaller hopper footprints.

Another area of concern is material plugging in the transfer line. As you might imagine, if the powder has a cohesive strength high enough to cause arching or ratholing, then it will likely have enough strength to create plugs in the transfer line.

Lastly, consideration needs to be given to efficiently getting the material discharged from the super sack. Establishing flow for these types of powders can often require additional means to establish and maintain material flow out the bottom spout of an FIBC / super sack.