Falling film evaporators are a prevalent type of evaporator used in various industries, known for their efficiency and effectiveness in handling large volumes of liquids. This evaporator type is particularly favored for its ability to provide rapid and uniform evaporation, making it ideal for heat-sensitive and low-viscosity liquids.

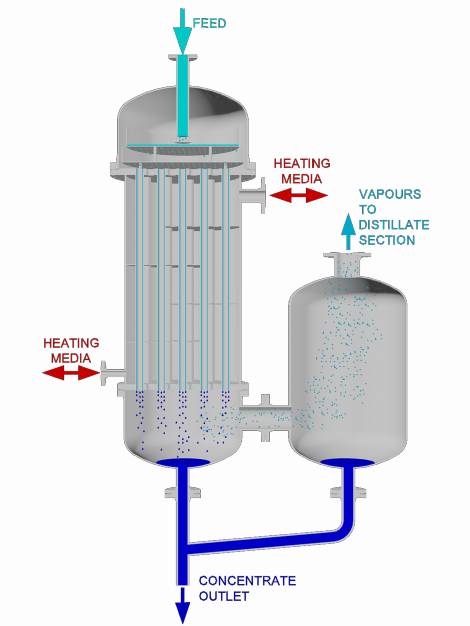

In a falling film evaporator, liquid feed is distributed at the top of a vertical tube bundle and flows downwards, forming a thin film along the heated tube walls. The heat is typically supplied through the tube walls from steam or another hot medium. As the liquid film descends, evaporation occurs, and the vapor separates from the liquid, enhancing the concentration of the solution.