Columns are typically used to perform chemical and/or thermal separations. But this requires some internal components, because without all that “stuff” inside, a bare column would be just a pipe.

The different elements installed inside columns are what help facilitate the separation process.

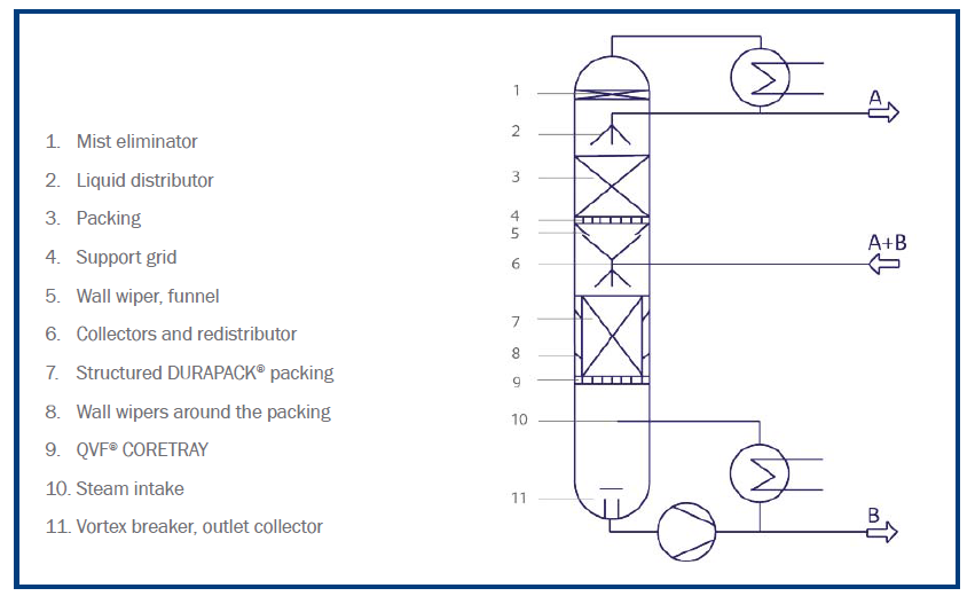

The diagram below shows typical components found in distillation. In this example, the packed distillation column is used for separating volatile substance A from less volatile component B:

Here’s a short explanation of what task each internal has in a column system (refer to diagram above for location):

1. Mist eliminator - Located at the head of the column, these are used to prevent entrainment at the vapor outlet. They can consist of packing or inert fabric.

2. Liquid distributor - This component evenly dispenses the incoming fluid over the column cross-section. The type used (channel, tube, nozzle, etc.) will depend on the different characteristics of your liquid.

3. Packing - Typically, Borosilicate glass structures are used for their temperature allowance and corrosion-resistance. Other materials are available if the conditions of your process require a different option.

4/9. Support grid/QVF CORE-Tray - Our QVF CORE-Trays provide effective support for structured packing, retaining most of the gas flow cross-sectional area and minimizing the pressure drop. Support grids made of different corrosion resistant materials are also used to hold the structure packing in place.

5/8. Wall wiper (funnel, around packing) - Liquid in a column has the tendency to want to run down the inner wall. A wall wiper works to deflect liquid from the column inner wall back into the packing to maximize column efficiency.

6. Collectors and redistributor - Positioned underneath the packing, collectors catch the run-down liquid and either remove it from the column or feed it back to the redistributor.

7. Structured DURAPACK packing - When a high level of separation efficiency is needed, structured packing is used to intensify process objectives. DURAPACK is comprised of alternating arranged corrugated plates of glass with flow channels inclined by 45°. The glass plates are fused together so that the borosilicate glass is the only material in contact with the process fluids.

10. Steam intake - Uniform steam distribution uses the packing efficiently, reducing the overall height of the column.

11. Vortex breaker, outlet collector - Located at the very bottom of the column, these help to ensure reliable liquid drainage and keep run-down liquid from entering the steam inlet.