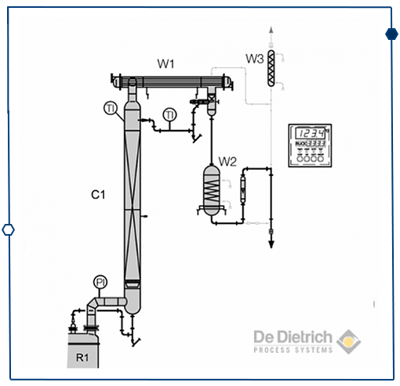

In practice, reaction and distillation processes are frequently executed consecutively. The chemical and pharmaceutical industries have been successfully using a combination of vessels with distillation attachments as a corrosion resistant solution to realize their reaction and distillation / rectification needs, as this dual solution is especially suited for the production of highly refined and high-purity products.

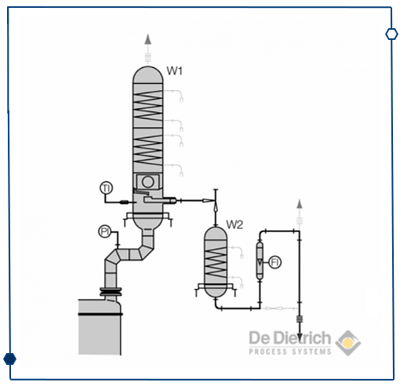

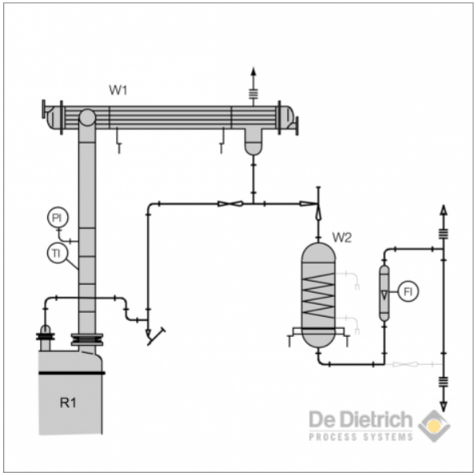

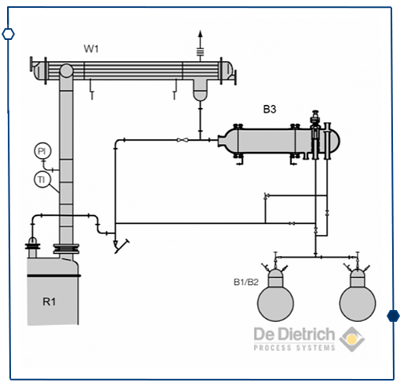

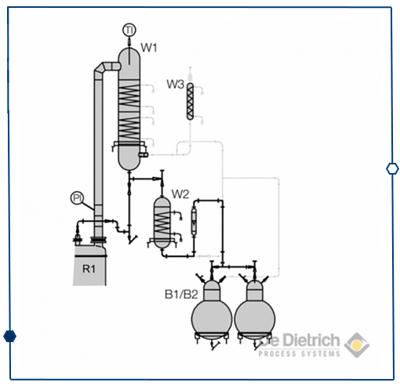

The vessel attachments can be flexibly connected via PTFE bellows directly to or laterally offset from the vapor outlet of the reactor. Vessel attachments are mounted in separate structures next to the vessels. The structure can be adapted individually to the available space conditions, leaving the required free space on the vessel cover for the stirrer unit, filling neck, illumination, sight glass, safety valves, and any other accessories and instrumentation. Since borosilicate glass is transparent, the process can be visually controlled at any time, improving the safety and reliability of the operation.

-1.png?width=508&height=461&name=system-overheads%20(1)-1.png)