Thin film evaporators are specialized devices used primarily in the chemical, pharmaceutical, and food industries to concentrate, separate, or purify liquids through evaporation. They are especially useful for processing heat-sensitive products or those with high boiling points.

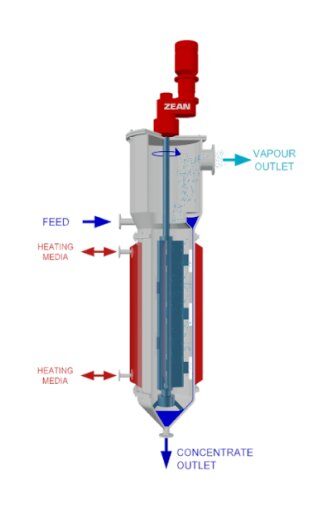

Thin film evaporators operate by spreading the liquid to be evaporated into a thin film over the surface of a heated tube or plate. This is usually achieved using a rotor or a wiper system inside a vertical or horizontal cylindrical body. The rotor generates high turbulence, which enhances the mass and heat transfer rates. As the film travels along the heated surface, rapid evaporation of the solvent occurs, leaving a more concentrated product.